In this video we went over how a car wash works. We started by looking at the computer that sends the signal to the PLC (programmable logic controller). That sends the type of wash that the customer wants to the PLC. The PLC then controls the outputs of the soap and the motors that power the wash. Part of the PLC are amp clamps. Amp clamps measure the amount of electricity that goes through them and then adjust the brushes based on the contours of the vehicle. We experimented with the computer and watched it move the brushes back to their home position.

The speed and direction of the machine are controlled by a VFD (variable frequency drive). The VFD takes an AC input and outputs different Hertz to spin the brushes.

Next we went inside and looked at the machinery on the inside of the car wash. We looked at the chemical pumps that took soap out of soap barrels and dispensed it to the car wash. After that we went outside and looked at a wire he had to replace. It took him a lot of work to fix it. Another thing he had to add was a speaker to the car wash so that people would know when to pull forward, stop, or back up.

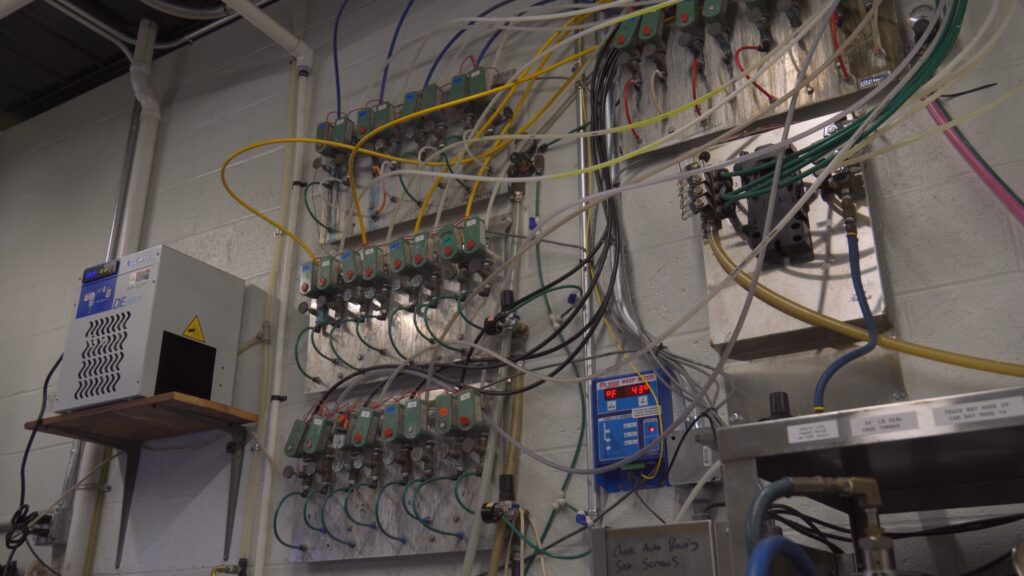

Inside again, we looked at the self-serve bay system. If a timer on the bay gets hot, it activates a contactor that turns on the high pressure water. Then it opens a system of solenoids that send out the soap.

To control the machine, Alex uses a HMI (human machine interface). On the HMI he can test any feature of the car wash. From it he can turn on the brushes and water.

After that we tried out the car wash. We had a GoPro on top and it added a bit of suspense. First it did a high pressure pass. That takes off layers of dirt. The amp clamps sensed the contour of the vehicle and went up around it. The car wash also washed the wheels with special sensors.

After the car wash we looked at his solar panels. The solar panels help with the rising cost of electricity.

In conclusion we had a great time shooting the video and meeting Alex.